The industry railway, in the interests of a constant search of it innovation and improves of railway vehicles, develops new solutions that allow it to reduce its consumption energy, improve its efficiency and increase its reliability.

This context marks the development of the European project Roll2Rail, an initiative coordinated by UNIFE and technically led by CAF, rail vehicles manufacturer. The project, started 2015, is part of the Shift2Rail initiative for research and innovation in the European rail sector. In Roll2Rail, the IKERLAN technology centre cooperates with CAF P&A in the development of electric traction equipment for trains based on silicon carbide se- miconductors.

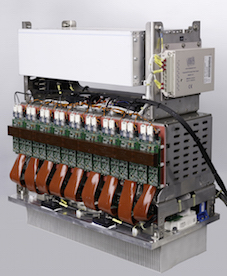

Silicon carbide is a material characterised by superior performance compared to that of conventional devices. These properties make it possible to reduce the volume and weight of current traction systems, which are vital parameters for improving the efficiency of rail trans- port.

Roll2Rail, which has received 16 million euro in funds, through the European Union’s Horizon 2020 research & innovation support programme, counts on the participation of the Basque manufacturer CAF Power & Automation and other renowned companies the rail transport sector.

The use of silicon carbide in the traction equipment developed in collaboration with CAF has allowed us to reduce the volume and weight of power cores by 30 % and that of the magnetic elements by 80 %. In addition, losses in the conversion system have been reduced by 50 %, a fact that has increased its efficiency in a remarkable way.

Project details

◗ Name: Roll2Rail

◗ Funding organisation: European Union

◗ Programme: Shift2Rail (Horizonte 2020)

◗ Contract: 636032

◗ Project coordinator: UNIFE

◗ Thecnical leader: CAF